Harkness Equipment began with selling outdoor wood furnaces, but evolved into supplying all your outdoor furnace supplies. In addition to selling the units, Harkness Equipment carries a complete line of hydrualic heating supplies, including insulated underground piping, in-floor piping, heat exchangers (either water-to-air or water-to-water), pumps, manifolds, fittings (black, stainless steel, copper), as well as pex compression and shark-bite fittings.

Portage and Main Ultimizer Wood Boiler BL 2840

Here are the specifications for your |

| The Ultimizer wood series is the product of more than 50 years of research and development that has earned Portage & Main Outdoor Boilers the reputation as an industry leader. With four sizes available, heating from under 2,000 sq ft to 12,000 sq ft, producing up to 500,000 BTUs. The Ultimizer can be connected to virtually any existing forced air or hydronic radiant heating system. Heat your home, domestic hot water, other buildings, hot tub, swimming pool, and more. |

Less Wood | Save MoneyPortage & Main conventional boilers have set the bench mark for efficiency for over 50 years. Our boilers burn 33 – 50% less fuel than any other brand |

Optimum burn | Save TimeOur R&D team designed a conventional/gasifier boiler to achieve optimal combustion with a refractory firepot lining |

12+ Hours Longer BurnOur technology turns smoke into usable heat. This sectional boiler design resulted in user friendly, low maintenance & higher efficiency boiler |

|

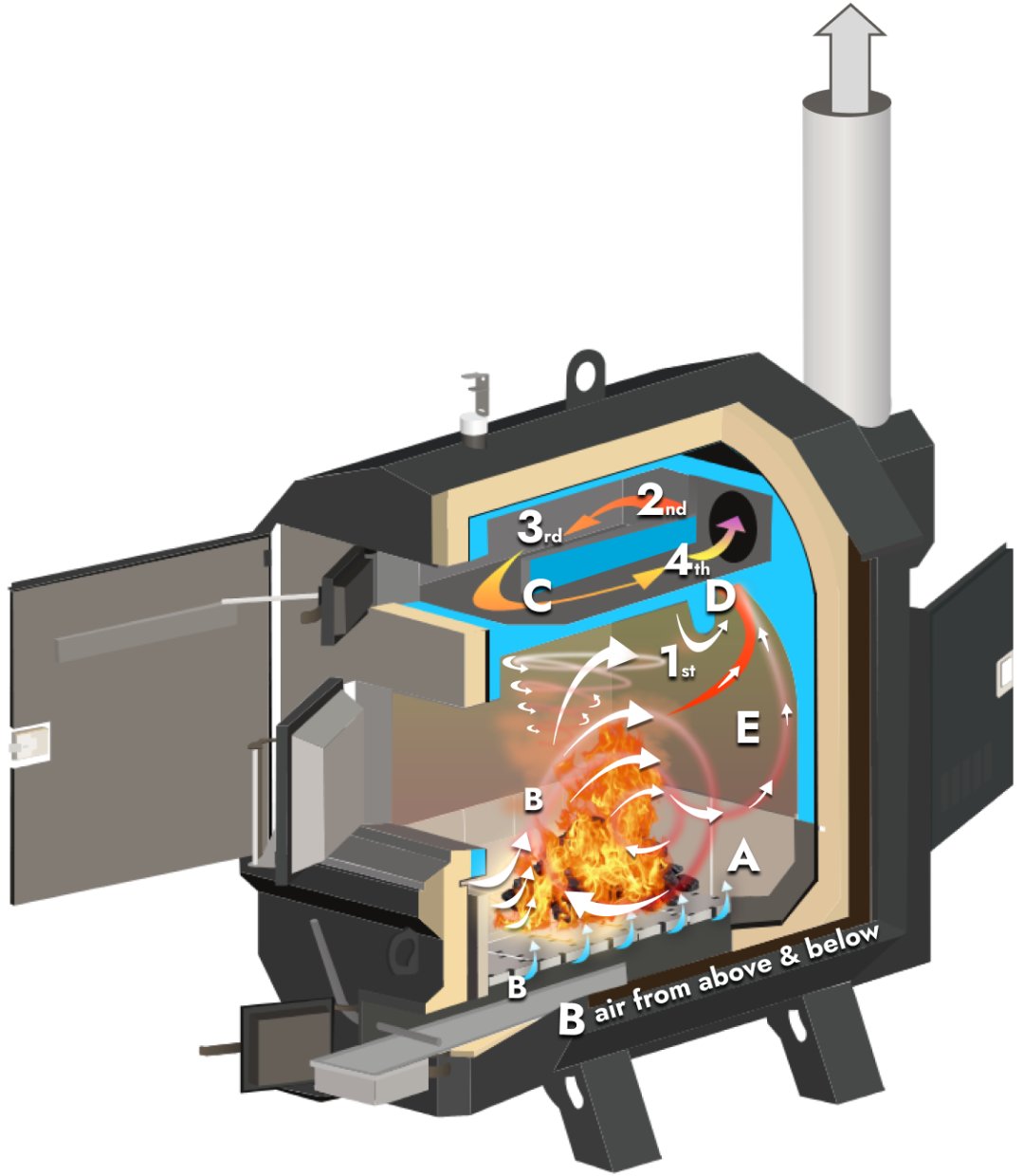

Legend1st : First pass |

A. Refractory Brick LiningThe Portage & Main Ultimizer is a refractory lined, dry base boiler. In the industry it has become known as an “updraft gasifier” because of its efficient burn. The Ultimizer is simple to use, easy to maintain and not fussy about the fuel it burns. It is very important to understand the “fire triangle” in order to fully appreciate the advantages of the Ultimizer design, and how it will save you fuel, money and time. To achieve a clean, efficient burn with complete combustion, an optimal balance of OXYGEN, HEAT & FUEL is required. The Portage & Main Ultimizer has been specifically designed to achieve this optimal balance. |

Dry base design, zero ash line corrosion & no bridgingThe heat stored in the refractory lining helps ensure that a more complete combustion process occurs. I.e. fuel is reduced to charcoal in a 3-stage process. STAGE 1: The fuel is heated to evaporate and drive out moisture. This starts at 212 degrees F STAGE 2: It starts to break down on a chemical level at 500 degrees F. Volatile matter is vaporized. These vapors contain 50% to 60% of the heat value of the fuel, making it imperative for them to be burnt properly at a temperature in the range 1100 degrees F for maximum combustion efficiency. When all the volatile gases have been released, the remaining material is charcoal STAGE 3: Charcoal burns at temperatures in excess of 1100 degrees F. Latent heat also helps in the re-ignition of the fire at the start of the next burn cycle. It also helps to dissipate moisture that is a result of the combustion process. The dry base boiler design gives a very hot burn. The water jacket sits above the brick line so it isn’t up against the fire, taking away the heat prematurely. This eliminates ash line corrosion and the fuel is completely burnt, resulting in considerably less ash. |

B. Air from above & belowExhaust gases make their 1st and 2nd pass at the top of the firebox where they move under and around a water-cooled baffle and into the heat exchanger. Gases then travel to the front of the boiler in a 3rd pass, make a 180 degree turn and move in a 4th pass to the back of the heat exchanger. In this way, all available heat is taken from exhaust gases before they exit the chimney. It gives up to 50% more heat transfer compared to other non water-cooled, non brick lined designs. |

C. Full length quad-pass heat exchanger and upper baffleThe Ultimizer heat exchanger runs the full length of the boiler. It is completely surrounded by water which gives maximum heat transfer. |

D. Water-cooled rear baffleThe water-cooled baffle at the rear of the Ultimizer fire pot absorbs heat and traps combustion vapors. Turbulence is created when air is introduced from below and above the fire. This turbulence provides an optimal burning environment for the vapors, leading to a hotter and more efficient burn. Also, by trapping the vapors, they are thoroughly burnt before entering the high efficiency heat exchanger. This heat exchanger is totally surrounded by water for maximum heat transfer. |

E. Sectional, easy to repair designNot a throwaway design like other brands are. The Ultimizer weighs substantially more than other brand boilers. That’s due to the heavy weight, long lasting, quality materials that go into our design. It provides a long-term, sustainable solution to your heating needs. At the end of its long life, the water jacket can be replaced. Just remove the top half of the boiler and bolt on a new top section, no welding required and your trusty boiler is good to go again. This means a very sustainable warranty, resulting in savings for the customer of several thousand dollars by rebuilding rather than replacing the entire boiler. |